Stritz Jewellery Group is a member of the International Colored Gemstone Association (ICA) and the Responsible Jewellery Council (RJC)

Our Manufacturing Process

Below is our flow chat

Step 1 - Marking

The first step involves marking the stone. The rough diamond will be fully assessed to determine the best way to cut it so that maximum value is extracted. This will involve looking at the inclusions and where they are situated and minimising the loss of rough

Step 2 - Cleaving

Not all diamonds go to the cleaver. However, the majority of large stones do. To cut a rough diamond down to a manageable size the cutter must cleave it along the diamond’s tetrahedral plane, where it is the weakest. A wax or cement mould holds the diamond in place while the cutter carves a sharp groove along the plane. The cutter places a steel blade in the groove and strikes it forcefully with a mallet, splitting the rough diamond in two. This is a highly skilled job – if the cleaver or the planner make any errors the diamond could end up shattered!

Step 3 - Sawing

Sometimes diamonds have to be cut where there is no plane of weakness and so cannot be done by cleaving. Instead, the cutter saws the diamond using a phosphor-bronze blade rotating at about 15,000 rpm. An increasing number of companies are investing in laser equipment to cut their diamonds as this is more efficient and precise. In fact, the accuracy is remarkable as there is no cutting edge to wear down. During the sawing step the cutter decides which parts of the diamond will become the table (the flat top of the stone with the greatest surface area) and the girdle (the outside rim of the diamond at the point of largest diameter). Only then will he proceed to cut.

Step 4 - Bruiting/Cutting

This technique gives diamonds their shape. When diamonds are cut by hand the technique is called “bruiting”. “Cutting” refers to bruiting by machine. When the cutter shapes diamonds by hand he relies on the diamond’s hardness as his tool – he uses diamonds to cut diamonds. He uses a small, stick-like instrument with a cement-filled bowl at the tip to hold the diamond. The diamond is inserted into the cement with just one corner exposed. Using one of these sticks in each hand, the cutter rubs the exposed diamond parts together to bruit them. In the mechanical process the diamond is placed in a lathe and another diamond in the lathe rubs against it to create the rough finish of the girdle.

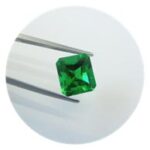

Step 5 - Faceting

There are two parts to faceting. The main facets are placed by a “lapper” (a grinder) and the remaining facets are created and polished by the “brillianteer” (a polisher). For example, in the case of a round diamond, the first 18 facets are outlined (by the lapper) and then the remaining 40 facets are completed by the brillianteer.

Step 6 - Polishing

To create the diamond’s finished look the cutter places it onto the arm above a rotating polishing wheel. The wheel is coated with an abrasive diamond powder that smoothes the diamond as it is pressed against the wheel. Finally, the diamond will be inspected carefully. Once approved, dust and oil will be removed by boiling the diamond in sulphuric and hydrochloric acid.

“Our main focus is on gaining total control of the supply chain so we can ensure transparency to our customers throughout the process.”

David Corvin

CEO of Stritz Jewellery

Our success in numbers

Stritz Jewellery Group is a member of the International Colored Gemstone Association (ICA) and the Responsible Jewellery Council (RJC)

Annual turnover to customers

Employees around the world

accuracy

Client Satisfaction

We maintain annual turnover of hundreds of millions of dollars to customers primarily located in the US and Europe

Our main focus is on gaining total control of the supply chain so we can ensure transparency to our customers throughout the process. We do that by holding agreements with mines directly to buy rough as well as owning our own factory located in Israel.

We can guarantee that our stones are natural, not pre-owned, and free of conflict.

About Us

Stritz was founded to fulfill a pressing need in the global Jewellery supply chain, a sole entity with complete control of the supply chain from rough to finished product. Founded, by Israeli-based Gemerald LTD and members of the IPSDE, Stritz commands total control of a supply chain stretching from Africa and Russia (rough selection/procurement) to Israel and Belgium (cutting/polishing) and onwards to China (finishing/setting). Exporting to businesses located around the world.

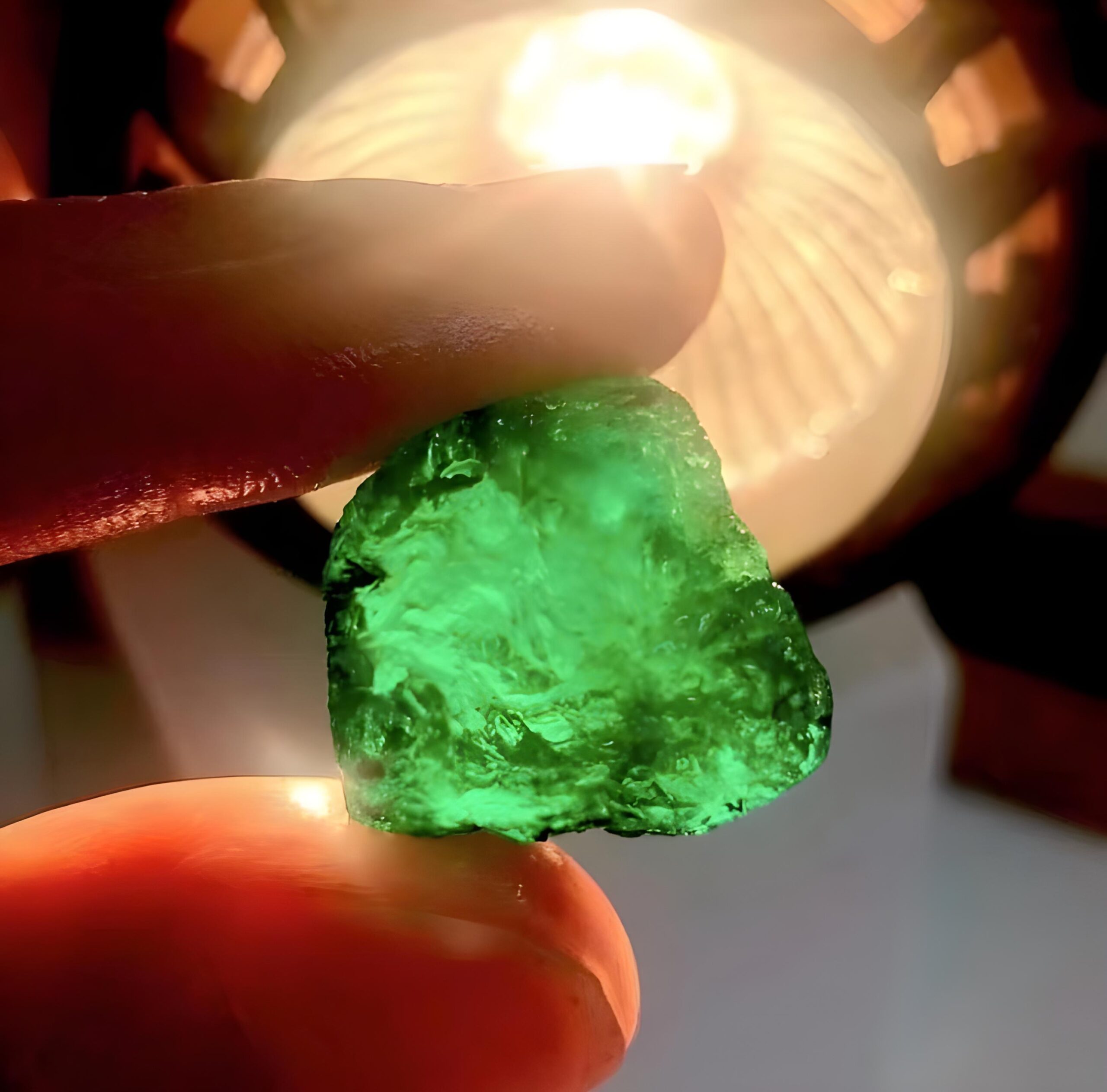

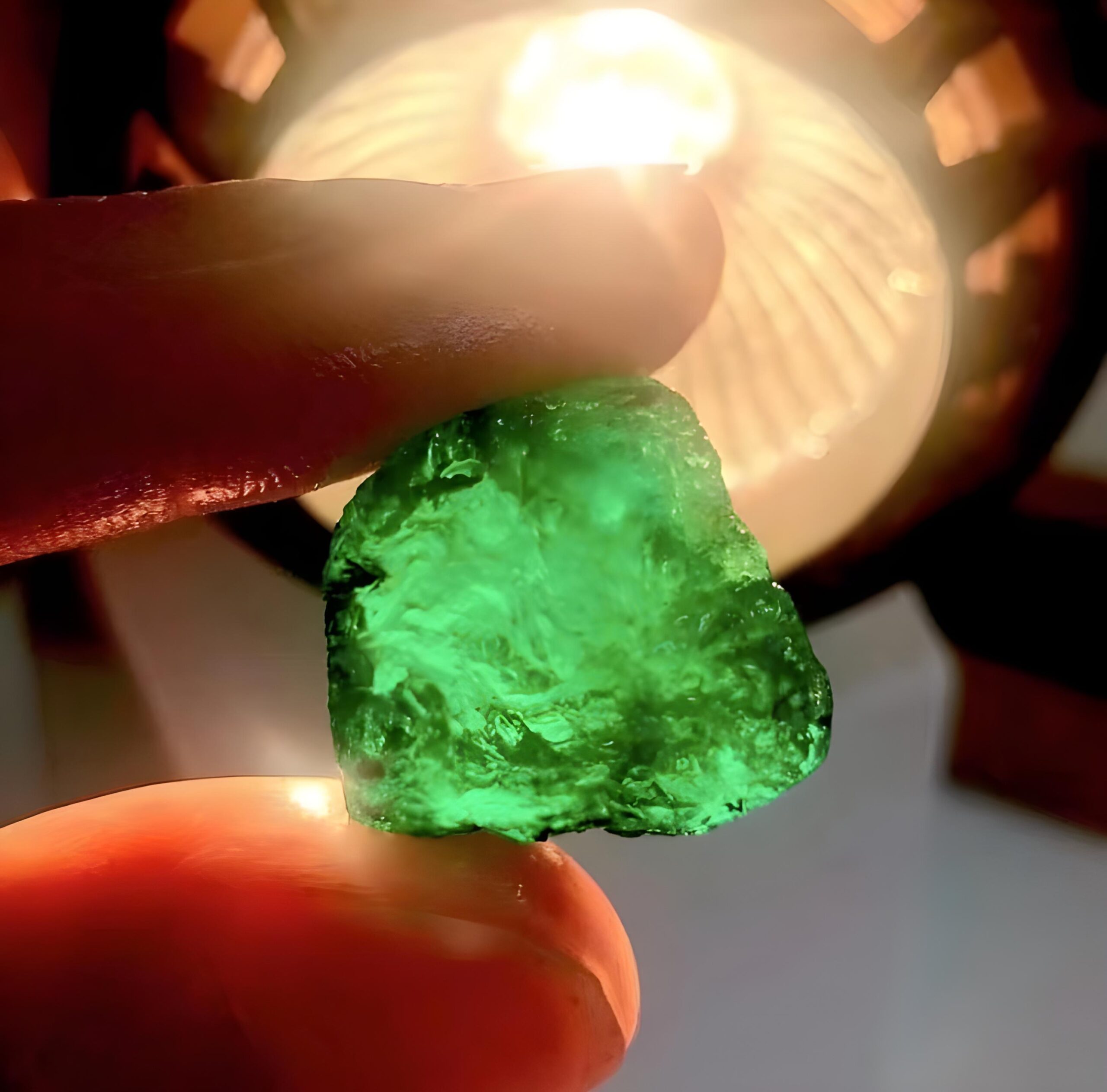

We hold exclusive sourcing agreements with gemstone and diamond mines in Africa as well as a partnership with Russia-based Alrosa.

We maintain an annual turnover of hundreds of millions of dollars to customers primarily located in the US and Europe.

Our Advantages

Our main focus is on gaining total control of the supply chain so we can ensure transparency to our customers throughout the process. We do that by holding agreements with mines directly to buy rough as well as owning our own factory located in Israel. We can guarantee that our stones are natural, not pre-owned, and free of conflict.

Our secondary focus is on mastering the cutting process. We are one of the few groups able to master the art of precision cutting through our factory in Israel. We are able to offer select clients the ability to cut rough into specially calculated carat weight. This could be the numeric digits of a birthday, anniversary, or another lucky digit.

Our Team

Founding Members

Tamir E.

African Sourcing

Idan

Israeli Factory Management

Amir G.

Stritz Jewellery Group Partner,

Hong Kong

Don’t hesitate to reach us

We are one of the few groups able to master the art of precision cutting through our factory in Israel.

Contact Us

Contact Us

Our Projects